ESD can cause a range of harmful effects of importance in industry, including gas, fuel vapour and coal dust explosions, as well as failure of solid state electronics components such as integrated circuits. These can suffer permanent damage when subjected to high voltages. The impact of such damages have resulted in several million dollar losses to some large manufactures& brands. In some cases it can be a loss of brand equity & losing customers when a defective product reaches customer.

Today with the growing technologically advanced manufacturing process every industry has the potential risks associated with ESD where human safety also have to be considered in addition to process safety.

SFATEC come as reliable partner under such situations in controlling & minimizing such risks that arise because of Electrostatic discharge. We can also supply Workwear which will have both flame resistant & ESD control properties simultaneously for very demanding situations where the chances of explosion are there.

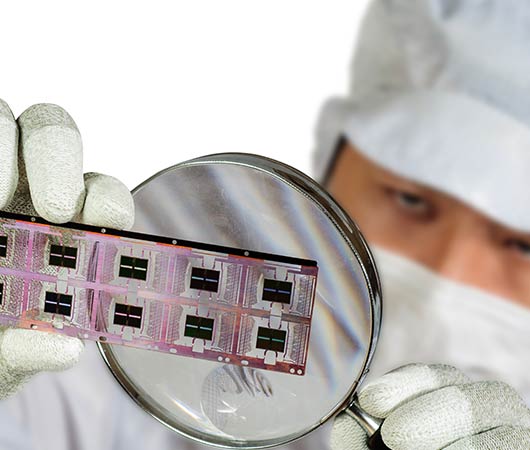

At SFATEC we are fully aware of your problems that many electronic components, especially microchips, can be damaged by ESD. Sensitive components need to be protected during and after manufacture, during shipping and device assembly, and in the finished device. Grounding is especially important for effective ESD control. It should be clearly defined, and regularly evaluated.

SFATEC suggests that for ESD prevention within an EPA(Electostatic discharge protected area) using the right ESD protective clothing meeting to standards of EN 1149-1/EN 1149-3 with conductive filaments on garments worn by assembly workers comes as the foremost important criterion in addition to conducting wrist straps, foot-straps to prevent high voltages from accumulating on workers' bodies, anti-static mats or conductive flooring materials to conduct harmful electric charges away from the work area and humidity control.

Currently as there are numerous ESD suppliers in the market without proper quality certification it will be foremost for you to select the right supplier like us to ensure the quality of process and enhance the damage control system that you may be already using in your assembly and other areas.

Further the full service ESD Workwear rental solution from SFATEC ensures that only the appropriate ESD fabric& sophisticated cleaning technology should be used for managing & maintenance of the ESD workwear. This guarantee no deterioration in the ESD levels of the used Workwear at any given time except for the normal wear & tear.

Under our special monitoring system which will be optional even 100% product monitoring for surface resistivity of the Workwear can be provided for customers whose process risks due to ESD is much higher.

Our full service model runs on latest European Workwear service IT platform which completely monitors every stage of service cycle & guarantees our customers with a trouble free operation. We can give you reports of the service usage by your employees to high levels of accuracy as every piece of work wear & delivery process is fully monitored by advanced Data Matrix technology.

Call on us and we would be much more glad to understand your process & suggest you the right ESD clothing service solution for your business.